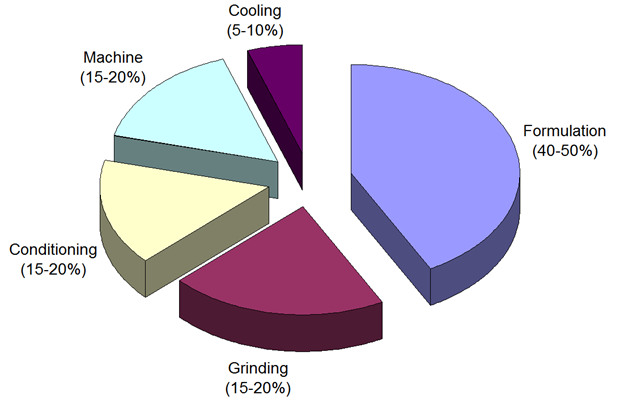

The factors influencing pellet quality are formulation, grinding, conditioning, type of machinery, and cooling. Still, it’s generally agreed that the formulation is the essential element affecting the process.

For example, the cereal grain used and its percentage can have a significant influence, and the inclusion of fats or oils (above 1%) can dramatically reduce pellet quality. But the fineness of the grind can also have a great deal of influence on the pellet: usually, the finer the grind, the better the quality, though you have to consider that excessively fine grinding creates problems in the digestive system of chickens. Particle size affects the extent of conditioning and particle bonding in the pellet.

In terms of pellet mill operations, the conditioning process greatly influences pellet quality (between 15% and 20%). Still, most feed producers try to solve pellet quality issues using a thicker die instead of optimizing the conditioning process.

This solves the problem but, at the same time, causes an unacceptable drop in production. Contrariwise, efficient conditioning increases the throughput capacity and, consequently, the production rate.

If excluding the formulation, the conditioning affects 30% of the pelleting process. During this phase, much attention must be paid to steam quantity and control, moisture content, retention time, and mixing action within the conditioner.

VSM helps entrepreneurs optimize their processes, operations, and site layout. We eliminate excessive processes and equipment to give you better value for your investments. For service inquiries and quotations, send us a message through WhatsApp, Viber or through our direct line +63 917 887 1285. Follow our Facebook Page for service updates.