Mastering the Mix: Techniques for Homogeneous Feed Blending

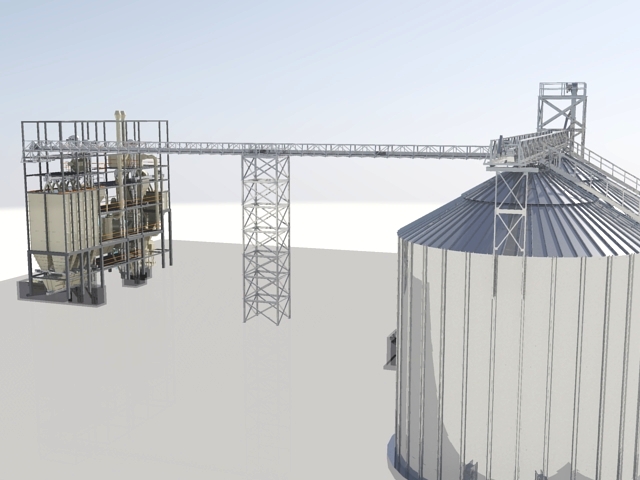

In the world of animal nutrition and feed production, achieving a homogeneous blend is crucial for ensuring consistent quality and optimal animal performance. A key player in this process is the feed mill contractor in the Philippines, who brings expertise in designing and implementing efficient blending systems tailored to local needs.

These contractors understand the unique challenges of the Philippine market, ensuring that feed blending techniques meet regulatory standards and livestock’s specific nutritional requirements. This blog post delves into the art and science of feed blending, exploring various techniques and best practices to help you master the mix while highlighting the valuable role of feed mill contractors in achieving excellence in feed production.

Understanding homogeneous feed blending

Before we discuss specific techniques, it’s essential to understand homogeneous feed blending and its importance.

What is homogeneous feed blending?

Homogeneous feed blending refers to the process of mixing various feed ingredients to create a uniform mixture in which each particle contains the same proportion of nutrients. This uniformity is critical for ensuring that animals receive a balanced diet with every bite they take.

Why is it important?

- Nutritional balance: A homogeneous blend ensures that each animal receives the intended balance of nutrients, regardless of how much they consume.

- Consistent performance: Uniform feed leads to more predictable and consistent animal growth and production.

- Cost-effectiveness: Proper blending prevents over or under-dosing of expensive ingredients like vitamins and minerals.

- Quality control: A homogeneous mix makes maintaining and verifying feed quality standards easier.

Key factors affecting homogeneous blending

Several factors can impact the homogeneity of your feed blend:

- Particle size: Ingredients with similar particle sizes tend to mix more evenly.

- Density: Differences in ingredient density can lead to segregation during mixing or transport.

- Moisture content: Varying moisture levels can affect how ingredients interact and mix.

- Electrostatic charges: Some ingredients may develop electrostatic charges, causing them to clump or repel each other.

- Equipment: The type, size, and condition of your mixing equipment play a crucial role in achieving homogeneity.

Techniques for achieving homogeneous feed blending

Now, let’s explore some effective techniques to master the art of homogeneous feed blending:

1. Proper ingredient sequencing

The order in which you add ingredients to the mixer can significantly impact blend homogeneity.

- Start with larger ingredients (grains, protein meals) to create a “base mix.”

- Add micro-ingredients (vitamins, minerals) in the middle of the mixing process.

- Introduce liquids (oils, molasses) towards the end of mixing to prevent clumping.

2. Utilize premixes

Creating premixes of micro-ingredients can greatly improve overall homogeneity:

- Combine small-quantity ingredients with a carrier (e.g., ground corn or soybean meal).

- This increases the volume, making it easier to distribute evenly throughout the main mix.

- Premixes also reduce the risk of errors in weighing tiny amounts of individual ingredients.

3. Optimize mixing time

Finding the right mixing time is crucial:

- Under-mixing results in poor homogeneity.

- Over-mixing can lead to ingredient segregation or unnecessary energy consumption.

- Conduct mixer efficiency tests to determine the optimal mixing time for your specific equipment and ingredient combination.

4. Implement particle size reduction

Reducing and standardizing particle sizes can significantly improve blend homogeneity:

- Use hammer mills or roller mills to grind ingredients to similar particle sizes.

- Consider the target animal when determining optimal particle size (e.g., finer for young animals, coarser for ruminants).

5. Address density differences

To combat segregation due to density differences:

- Use binders or pelletizing to lock ingredients together.

- Consider liquid coating to help lighter particles adhere to heavier ones.

- Adjust mixer fill levels to optimize the mixing action for ingredients with varying densities.

6. Manage moisture content

Controlling moisture is essential for achieving a homogeneous blend:

- Aim for a consistent moisture content across ingredients (typically 12-14% for most dry feeds).

- Use moisture analyzers to monitor and adjust moisture levels as needed.

- Consider adding water or steam during mixing to achieve the desired moisture content and improve particle cohesion.

7. Leverage technology

Modern technology can significantly enhance your blending precision:

- Utilize computerized batching systems for accurate ingredient weighing and sequencing.

- Implement near-infrared (NIR) spectroscopy for real-time nutrient analysis and blend adjustments.

- Use radio-frequency identification (RFID) tags to track ingredient lots and ensure proper inclusion.

8. Regular equipment maintenance

Well-maintained equipment is crucial for consistent blending:

- Regularly inspect and replace worn mixer paddles or ribbons.

- Check for and repair any dead spots where ingredients might accumulate in the mixer.

- Calibrate scales and metering devices regularly to ensure accurate ingredient inclusion.

9. Implement quality control measures

Robust quality control procedures are essential:

- Conduct regular mixer efficiency tests using tracers (e.g., salt, iron filings, or dyed particles).

- Analyze samples from different parts of the batch to verify homogeneity.

- Use statistical process control charts to monitor and improve blending consistency over time.

10. Train and educate staff

Well-trained personnel are vital in achieving consistent homogeneous blends:

- Provide comprehensive training on ingredient properties, mixing principles, and equipment operation.

- Foster a culture of precision and attention to detail among your mixing staff.

- Regularly update training to incorporate new technologies and best practices.

Conclusion

Mastering the art of homogeneous feed blending is a continuous learning, optimization, and quality control process. You can consistently produce high-quality, uniform feed blends by implementing these techniques and staying attuned to the unique characteristics of your ingredients and equipment.

Remember, the goal is not just to mix ingredients but to create a nutritionally balanced, homogeneous blend that supports optimal animal health and performance. With patience, precision, and the proper techniques, you can elevate your feed production to new levels of excellence.

As you continue to refine your blending processes, always be open to new technologies and methodologies. The field of animal nutrition is constantly evolving, and staying ahead of the curve in feed blending techniques can give you a significant competitive advantage in the market.

By mastering the mix, you’re not just producing feed – you’re crafting the foundation for healthy, productive animals and a thriving agricultural industry. So, roll up your sleeves, fire up those mixers, and let’s blend our way to success!

Perfect your blend, perfect your results! Master homogeneous feed blending techniques now. Elevate your livestock nutrition and see the difference in animal performance. Start mixing smarter today!