Quality Assurance in Feed Mills: Ensuring Safe and Nutritious Animal Feed

Imagine a world where the steak on your plate or the milk in your glass starts with the humble animal feed. That’s our reality! Animal feed quality is the unsung hero of livestock farming, silently shaping the food on our tables. It’s not just about keeping animals full; it’s about boosting their health, supercharging productivity, and even influencing the flavors we enjoy.

But it’s not all smooth sailing. Today’s feed industry navigates a sea of challenges, from sourcing ingredients globally to adapting to climate curveballs. This is where feed mills and feed mill contractors in the Philippines step in, armed with rigorous quality checks and cutting-edge tech. They’re the guardians of our food chain, ensuring that from farm to fork, quality remains king.

Philippine Regulations and Standards for Feed Mill Operations

In the Philippines, feed mills must follow rules set by the Bureau of Animal Industry (BAI) under the Department of Agriculture. These rules aim to ensure feed safety and quality. The main law governing feed production is the Republic Act No. 1556, also known as the Livestock and Poultry Feeds Act.

Key aspects of Philippine feed regulations include:

- Registration: All feed mills must register with the BAI. They need to renew this registration regularly.

- Ingredient Control: The BAI provides a list of approved feed ingredients. Mills must only use ingredients from this list.

- Labeling Requirements: Feed packages must clearly show what’s inside, including nutrient levels and any medication.

- Quality Standards: The Philippine National Standards (PNS) set specific requirements for different types of animal feed.

- Inspection and Monitoring: BAI officials regularly check feed mills to make sure they follow the rules.

- Testing: Feed samples must be tested in accredited laboratories to check for quality and safety.

- Record Keeping: Mills must keep detailed records of production, ingredients used, and where feed is sold.

- Worker Training: Feed mill staff must be trained in proper feed production and safety practices.

Following these rules helps Philippine feed mills produce safe, high-quality feed. It also builds trust with local farmers and helps support the country’s growing livestock industry.

Key Components of a Quality Assurance Program in Feed Mills

A good quality check program in feed mills should have these parts:

- Ingredient Checks: Testing all incoming materials to make sure they’re good enough to use.

- Process Control: Watching every step of making feed to keep quality high.

- Sampling and Testing: Regularly checking finished feed to make sure it has the right nutrition and is safe.

- Tracking: Keeping good records to follow ingredients and products from start to finish.

- Worker Training: Teaching all feed mill workers how to follow quality rules.

- Always Getting Better: Regularly looking at the quality program and making it better.

By doing all these things, feed mills can make sure they always produce safe, nutritious animal feed.

Best Practices for Feed Mill Operations

To make their quality checks work well, feed mills should follow these good habits:

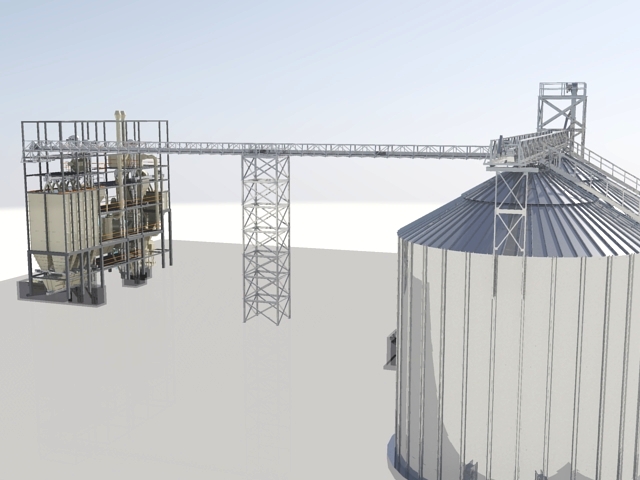

- Smart Building Design: Set up the feed mill in a way that makes it easy to work and stay clean. Keep everything in good shape and update when needed.

- Careful Ingredient Handling: Choose good suppliers and store materials the right way.

- Checking the Process: Make sure all the steps of making feed work well and keep an eye on them all the time.

- Good Testing: Have a lab in the feed mill or work with outside labs to test feed regularly.

- Keeping Good Records: Write down everything about how the feed is made and where it goes.

- Always Improving: Keep looking for ways to make things better and check the work often.

These good habits help feed mills make reliable, consistent animal feed.

Benefits of Outsourcing Feed Mill Operations

Some companies choose to let other experts handle their feed mill work. This can have some good points:

- Expert Knowledge: Feed mill experts often know a lot about making feed and following rules.

- Saving Money: Bigger feed mill companies might be able to make feed for less money.

- Flexibility: It’s easier to change how much feed you make when someone else handles it.

- Less Money Upfront: Companies don’t have to spend as much to build their own feed mills.

- Better Quality Checks: Feed mill experts often have very good ways to check feed quality.

Working with a good feed mill company can be a smart way to get better, cheaper animal feed.

Conclusion

Keeping animal feed safe and good quality is very important for feed mills. By having strong quality checks, feed mills can make sure their feed is safe and nutritious. This helps keep farm animals healthy.

Following rules, using good practices, and sometimes working with feed mill experts can help the whole farming business do well. Good quality checks don’t just help farmers and animal owners. They also help keep food safe for everyone.

Whether a company makes its own feed or gets help from others, the goal is the same: to make animal feed that keeps animals healthy and growing well, while also keeping the food we eat safe. By focusing on making good feed, the farming business can keep up with the growing need for animal products in a safe and lasting way.