Innovative Feed Mill Design: Enhancing Safety and Efficiency in the Philippines

Feed mills play a crucial role in the agricultural industry, responsible for transforming raw materials into high-quality animal feed. The demand for efficient and safe feed mill operations has never been more pressing in the Philippines, where the livestock and poultry sectors are thriving. Innovative feed mill design has emerged as a key strategy to address the evolving needs of this dynamic industry.

At the heart of feed mill design is carefully considering various factors, from material handling and processing to safety protocols and environmental impact. Balancing productivity, safety, and sustainability requires a deep understanding of the industry’s best practices and the latest technological advancements.

Safety Considerations in Feed Mill Design

Safety is of paramount importance in the feed mill industry, as these facilities often handle a vast array of hazardous materials and operate heavy machinery. Innovative feed mill design must prioritize the well-being of workers and the surrounding community, ensuring that all safety protocols are meticulously planned and implemented.

One of the primary safety considerations in feed mill design is dust control. Feed ingredients, such as grains and powders, can generate significant amounts of airborne particulates, which pose a serious risk of explosion and respiratory hazards. Innovative feed mill designers must incorporate state-of-the-art dust collection systems, ventilation, and explosion-proof equipment to mitigate these risks.

Another critical safety aspect is the handling and storage of chemicals, such as those used for feed additives and sanitization. Proper containment, labeling, and access control measures are essential to prevent accidents and minimize the risk of environmental contamination.

Efficiency Enhancements in Feed Mill Design

Efficiency is a key driver in the feed mill industry, as it directly impacts the facility’s productivity, profitability, and environmental footprint. Innovative feed mill design aims to optimize every aspect of the operation, from material handling to energy consumption.

One of the most significant efficiency enhancements in feed mill design is the integration of automation and digital technologies. Automated material handling systems, process control algorithms, and real-time monitoring tools can significantly reduce human error, improve process consistency, and enhance overall throughput.

Another area of focus in innovative feed mill design is the optimization of energy usage. Feed mill operators can significantly reduce their energy consumption and carbon footprint by incorporating energy-efficient equipment, such as high-performance motors, variable-frequency drives, and waste heat recovery systems.

Choosing the Right Feed Mill Designer

Selecting the right feed mill designer is crucial to the success of any feed mill project. These professionals possess the specialized knowledge and expertise required to navigate the complex landscape of feed mill design, ensuring that the final product meets the highest safety, efficiency, and sustainability standards.

When choosing a feed mill designer, looking for individuals or firms with a proven track record in the industry, a deep understanding of local regulations and best practices, and a commitment to innovation is essential. Additionally, the designer should be able to work closely with the feed mill operator to understand their unique needs and tailor the design accordingly.

Key Components of an Innovative Feed Mill Design

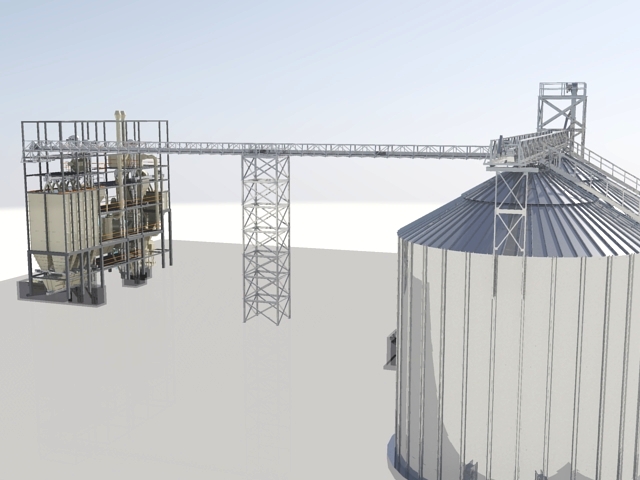

An innovative feed mill design encompasses a wide range of components, each playing a crucial role in the overall efficiency and safety of the operation. Some of the key elements include:

- Material Handling Systems: Automated conveyor belts, bucket elevators, and pneumatic transfer systems to efficiently move raw materials and finished products throughout the facility.

- Processing Equipment: High-performance grinding, mixing, and pelleting machines that ensure consistent product quality and minimize energy consumption.

- Dust Control Systems: Advanced filtration and ventilation systems to maintain a safe and clean working environment.

- Safety Monitoring and Alarm Systems: Comprehensive monitoring and alarm systems to detect and respond to potential hazards, such as explosions or chemical spills.

- Waste Management and Recycling: Innovative solutions for properly disposing and recycling waste materials, reducing the facility’s environmental impact.

- Digital Integration: Seamless integration of automation, data analytics, and remote monitoring tools to optimize process control and decision-making.

Final Thoughts

Innovative feed mill design is critical in the Philippines’ efforts to enhance the safety, efficiency, and sustainability of its livestock and poultry industries. By prioritizing safety, embracing technological advancements, and optimizing every aspect of the operation, feed mill designers can help propel the industry forward, meeting the growing demand for high-quality animal feed while minimizing the environmental impact.

To learn more about how innovative feed mill design can transform your operations, contact our team of experienced feed mill designers today. Our experts will work closely with you to develop a customized solution that meets your unique needs and exceeds your expectations.